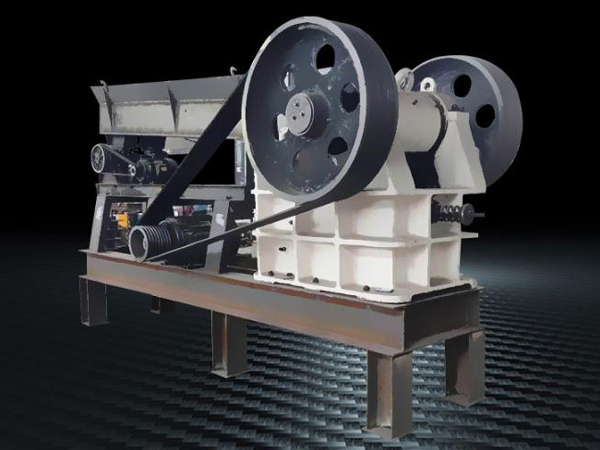

Jaw crushers are primary crushers used in an ore processing or mining plants. The size of these jaw crushers is determined by the square or rectangular opening from the feed opening (top of the jaws). For example, the 24 X 36 jaw crusher will have an opening of 24″ X 36″. while a 56 X 56 jaw crusher will have an opening of 56″ square.

In most cases, the main jaw crushers will have a square-opening design, while the secondary crushers have rectangular-opening designs. However, there are exceptions to these rules.

The main function of a jaw crusher is to reduce large-sized ore or rocks with the use of compression. The fixed jaw, which is typically positioned in a “V” alignment is a stationary “breaking surface”. The jaw that moves exerts force or pressure onto the rocks by forcing these materials against a stationary plate. The area just below the “V” aligned plates is known as the crusher’s size gap of the product or the actual size of the materials that are crushed inside these jaw crushers. The rocks will remain inside the jaws until they are broken down into small enough pieces to pass out of the gap or space on the bottom jaw.

How Does A Jaw Crusher Work?

A jaw crusher uses a compressive force in order to break large materials down into more manageable and smaller pieces. This equipment features 2 crushing jaws, one that is stationary, while the other moves. This action produces a mechanical pressure used to crush materials. The 2 vertical jaws include a V-shaped opening which is known as a crushing chamber.

The main applications that necessitate the use of a jaw crusher include:

Reducing construction or building rubble into smaller pieces

Crushing various types of ore

Rock ranging from extremely hard to medium rocks

Breaking down large pieces of glass

Crushing hard materials

In a single-toggle jaw crusher, the part of the crusher that moves operates in elliptical patterns. In a double-toggle jaw crusher, pendulum motions are used to crush harder materials. The eccentric shaft generates this force, which transfers to a crushing zone via a toggle plate system. The spring-pulling rods generate a non-positive connection, while the centrifugal masses positioned on the eccentric shaft compensate the heavy loads.

Due to the angle between the crushers, the materials fed into the jaws can easily reduce as they enter the crushing-chamber. The crusher settings are adjustable and the tooth form selected will define the size of the crushed material. The wedge system is also adjustable and allows for various adjustments. Every part of these adjustable systems are easily accessed and also require no or little maintenance.

Every toggle plate that is used in a jaw crusher uses maintenance-free temperature-pressure replaceable bars. The lubrication system ensures an adequate supply of grease to each bearing point.

Jaw crushers are available in various sizes and shapes to match up to different types of crushing requirements. The 2 most common jaw crusher types include the single-toggle jaw crusher and the double-toggle jaw crusher.